Hot Melt Adhesive Membrane Hot Melt Adhesive Film Nonwoven Fabric Interlining Double-Sided Adhesive for Carpet Composite

| Packaging information: |

|

|---|

1. Introduction to the Double Prosperity Hot Melting Glue Mesh Film Products

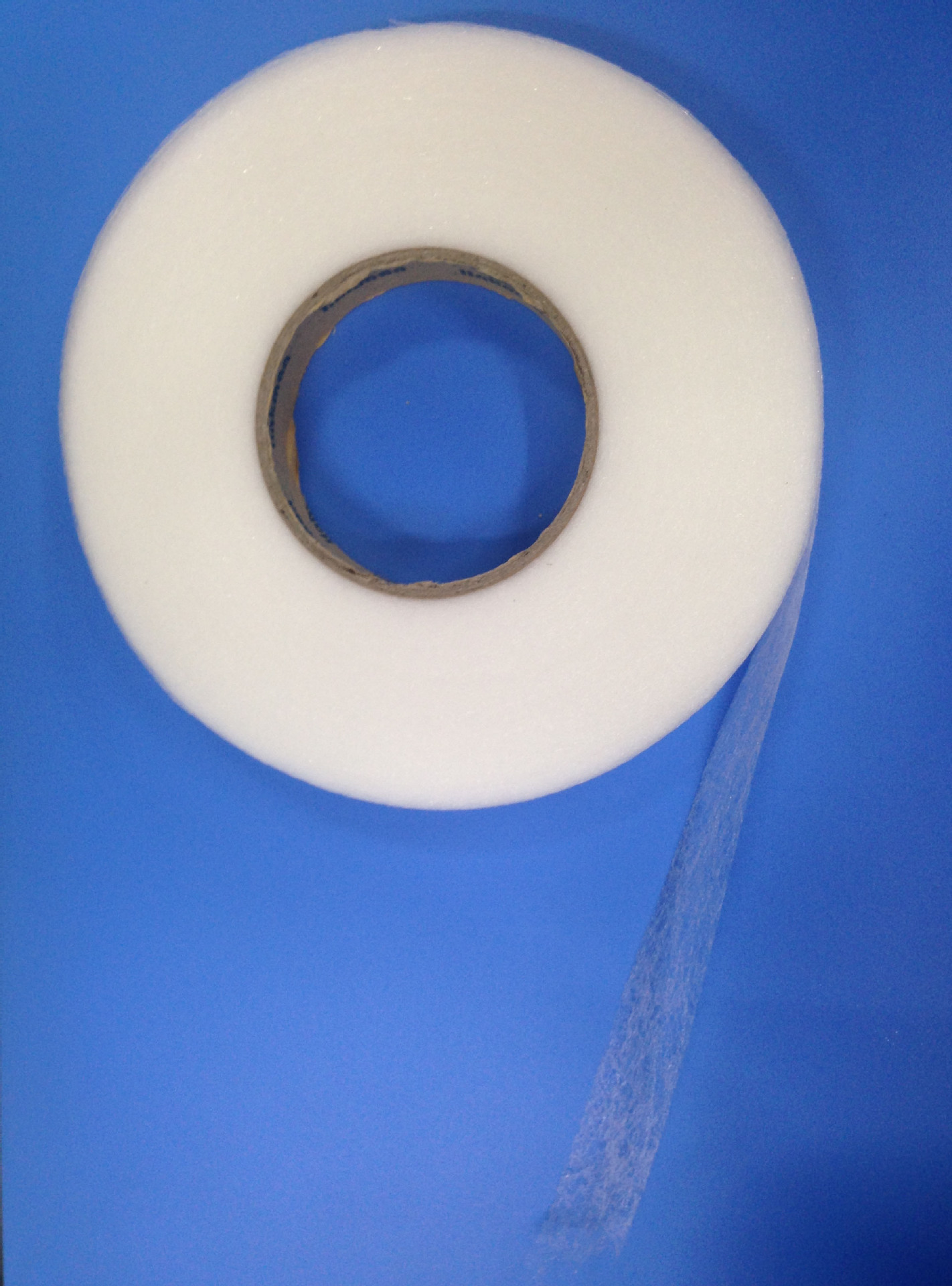

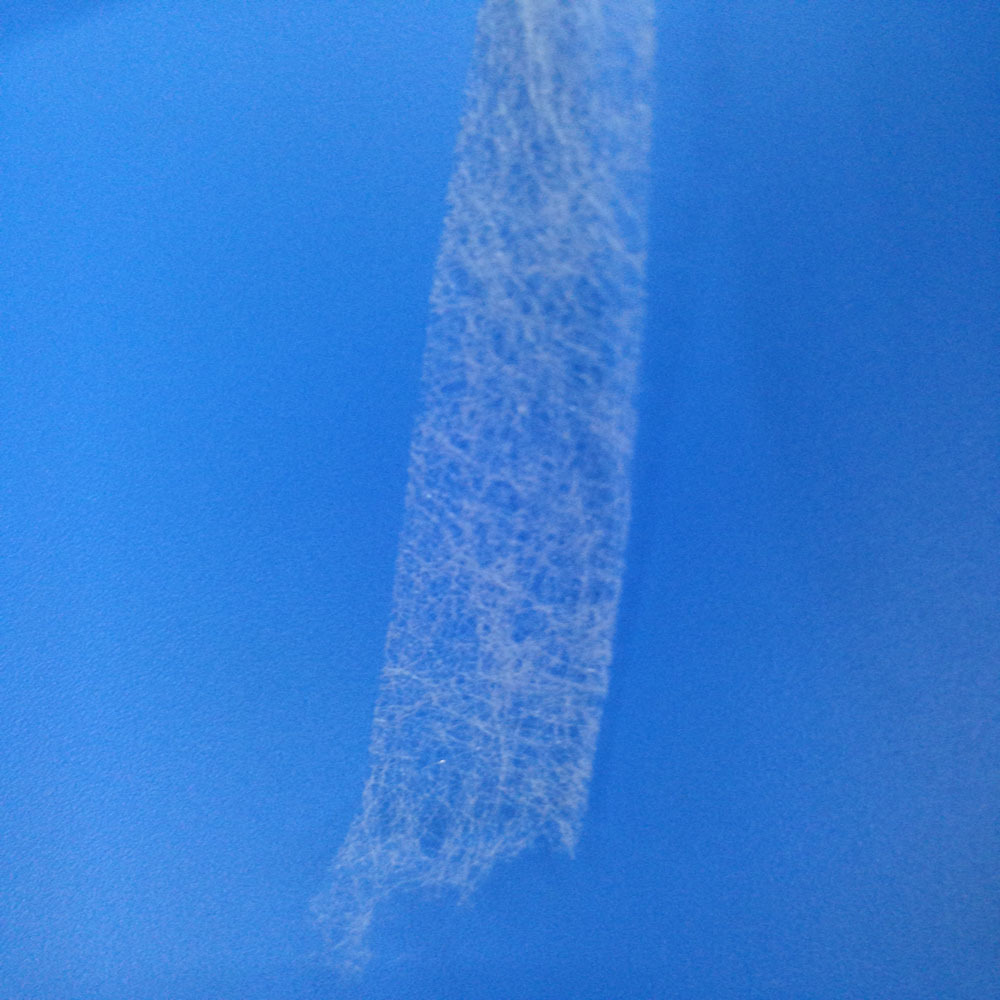

Appearance: White transparent mesh

Material: PA (Polyamide)

Width: Customized according to customer requirements, available in roll form or cut into disks.

Length: Customized according to customer requirements.

Melting point: 110-120"℃" is the symbol for Celsius temperature scale.

Suggested construction temperature: 120-150"℃" is the symbol for Celsius temperature scale.

Suggested processing pressure: 1.0-2.0kg/c?O

Suggested processing time: 8-15 seconds

We offer hot melt adhesive mesh films made from materials such as PES, EVA, and TPU.

2. Introduction to Hot-Melt Glue Mesh Film

Hot melt adhesive film, which feels non-sticky at room temperature, becomes sticky when the adhesive layer melts due to heat. It is made by melting hot melt adhesive raw materials through a melt-spinning and weaving machine, which creates a spider web-like structure similar to nonwoven fabric. When using, it is placed directly between two materials to be bonded, and after a period of heat pressure at a certain temperature, the bonding of the two materials is achieved.

Hot melt mesh film (double-sided tape) is a type of hot melt adhesive that is made by drawing, weaving, and coiling to form a mesh-like fabric. It has dual-sided adhesive properties and is an indispensable accessory in clothing production. During the processing of hot melt mesh film, no harmful solvents are added, and only the physical state of the hot melt adhesive is changed, inheriting the environmental protection, wide range of adhesive, and rapid adhesive characteristics of hot melt adhesive.

3. Features of Hot-Melt Glue Mesh Film

1This product is dry-cleanable, has good washability, does not foam, does not crease, does not leak glue, has a soft and elastic feel, and is widely used in both daily life and industrial applications as a composite material.

2Low processing temperature?p Saving labor?p Good flexibility?p Good breathability, strong adhesiveness?p Environmental protection and other characteristics.

3. The product is non-toxic, odorless, and non-polluting, making it an ideal eco-friendly adhesive material. It is widely used in paper packaging, footwear and apparel accessories, industrial assembly, electronics and electrical appliances, woodworking furniture, toy craft products, metal products, plastics, book covers, and inner lining hot melt adhesive bonding.

Section 4: Major Application Areas

Drink category: Automated box sealing for packaging of drinks, instant noodles, beer, etc.

Shoe materials: Suitable for the inner lining of the shoe front, the waist and abdomen, the inner lining of the shoe tongue, and the turning foam cotton. The shoe upper adhesive has good thermal adhesive properties, is not easy to yellow, and has high bonding strength.

Clothing: The pleats, smooth seams, belts, ties, shoulder pads, etc., on the front of the garment, the cuffs, the hem, the collar, and the bottom of the garment.

Home textiles: sheets, bedspreads, mattresses, pillowcases, tablecloths, curtains, etc.

Automotive: Adhesive for car roof, cabin insulation floor, sound-absorbing board, seat decorations, etc.

Material composite: The production of various textile fabrics, sponges, nonwoven fabrics, footwear and hats, leather goods, furniture, wood industry, sports equipment, interior decoration, sound insulation and heat insulation materials, and the adhesion between materials, etc.

Contact Information

Fixed phone: 0579-85838768

Mobile phone: 15858947177

QQ:867023223

Welcome to call, send messages or consult online!