cable zip ties 24 inch x0.49 inch self-locking electrical cable ties 250 pound strength plastic ties

| Packaging information: |

|

|---|

1. Plastic tie also known as: Tie, Tie Band, Tie Band, Nylon Tie, Tie Band, Tie Band, Electronic Tie.

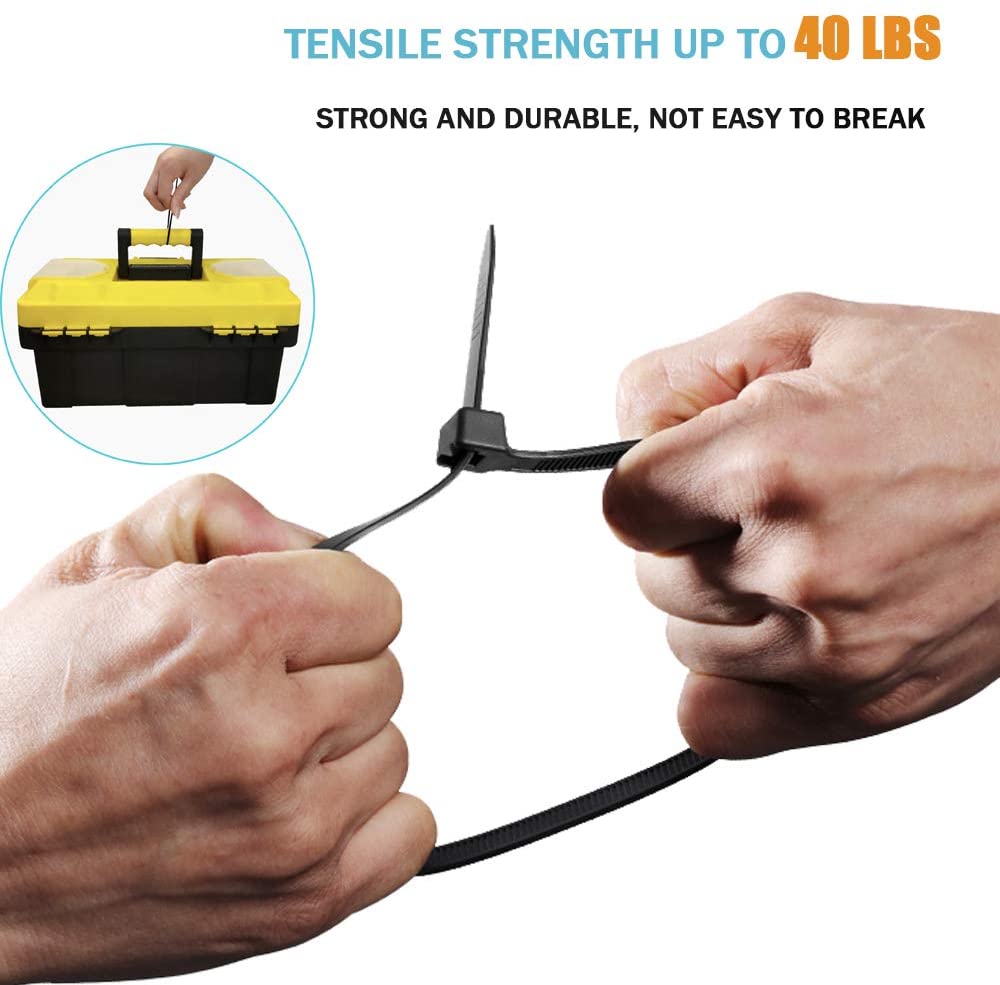

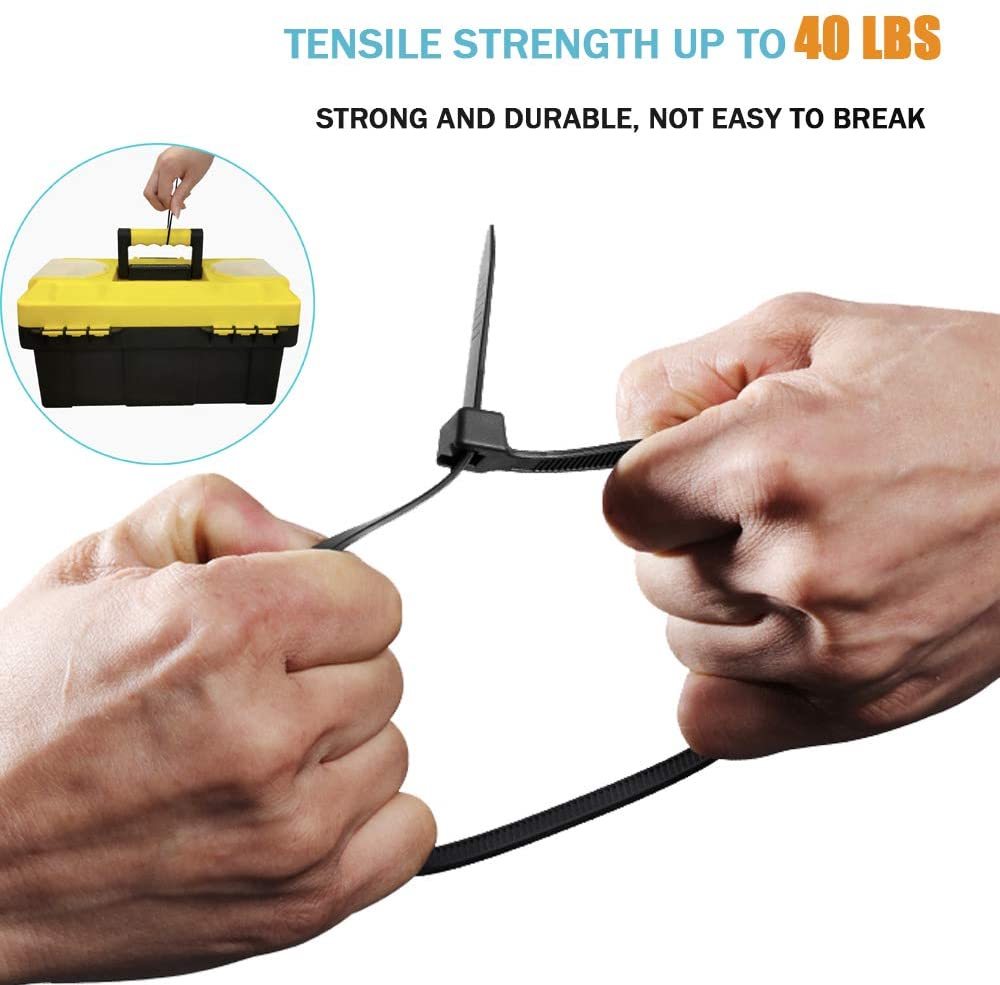

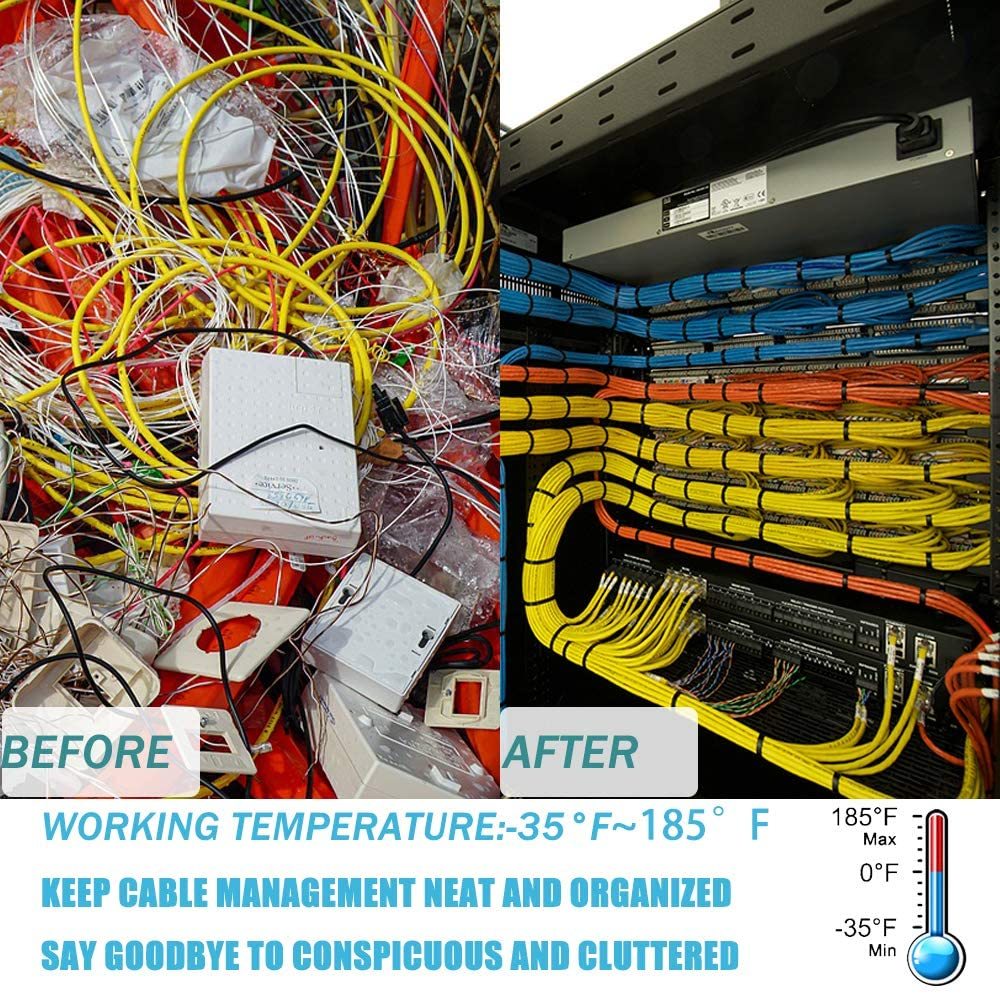

2. The product is made of Nylon 66 (UL-approved) material injection molded, with a fire rating of 94V-2. It has good acid and corrosion resistance, insulating properties, is not easily aged, and has strong durability. The operating temperature range is -40 to 90 degrees Celsius. This product features fast binding, good insulation, self-locking fixation, and convenience of use.

3. Plastic tie due to the special nature of the product (thin wall, large product injection molding process), its mold, injection molding process, and materials are quite precise. Generally, new manufacturers need a long period of trial and error to produce qualified products.

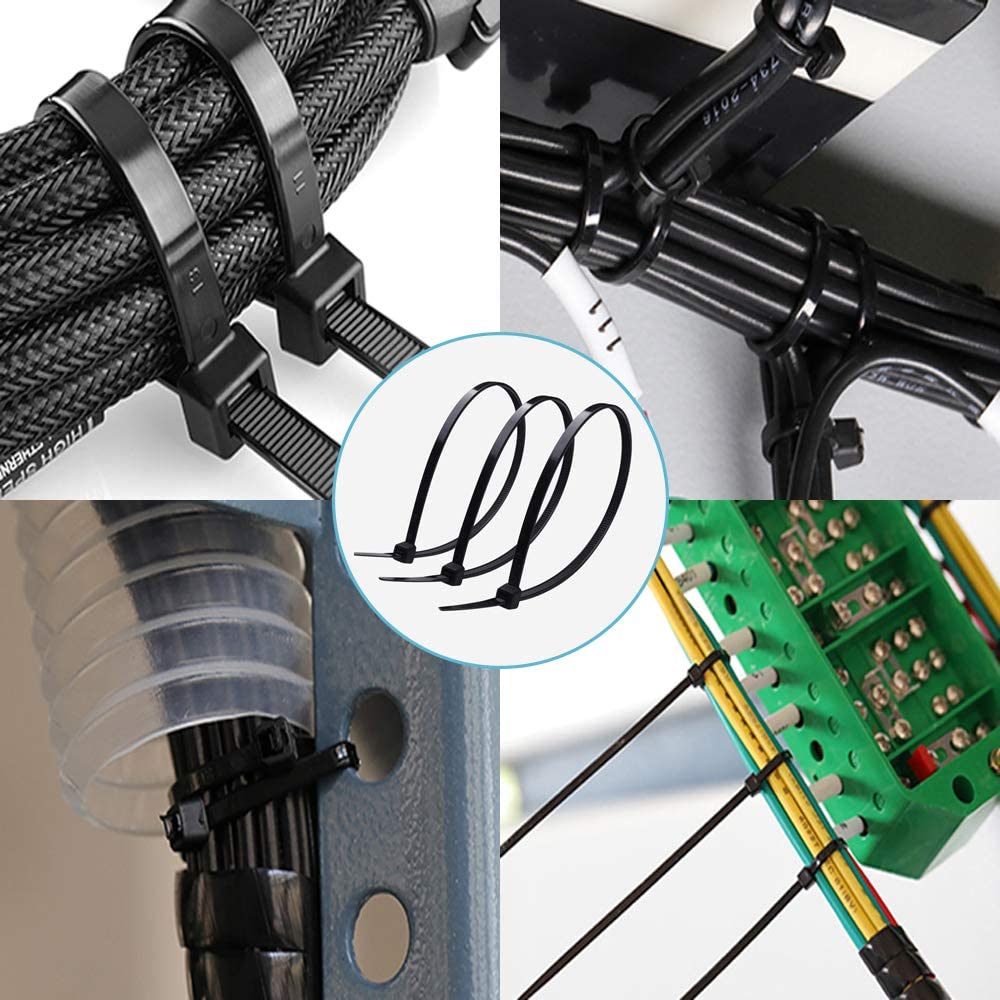

4. Cable ties, also known as tie wires, binding straps, or locking straps, are strips of material used to secure objects. They are generally classified by material into nylon cable ties, stainless steel cable ties, and sprayed stainless steel cable ties, and by function into standard cable ties, removable cable ties, label cable ties, fixed lock cable ties, latch cable ties, and heavy-duty cable ties, etc.

5. The zip ties are made of Nylon-66 material approved by UL, with a fire resistance rating of 94V-2. They are resistant to acid, corrosion, have good insulation properties, are not easily aged, are light in weight, and have strong bearing capacity. The operating temperature range is -40 to 90 degrees Celsius. The comprehensive mechanical properties of these zip ties are far superior to those of general engineering plastics, making them an ideal material to replace copper, stainless steel, and other non-ferrous metals.

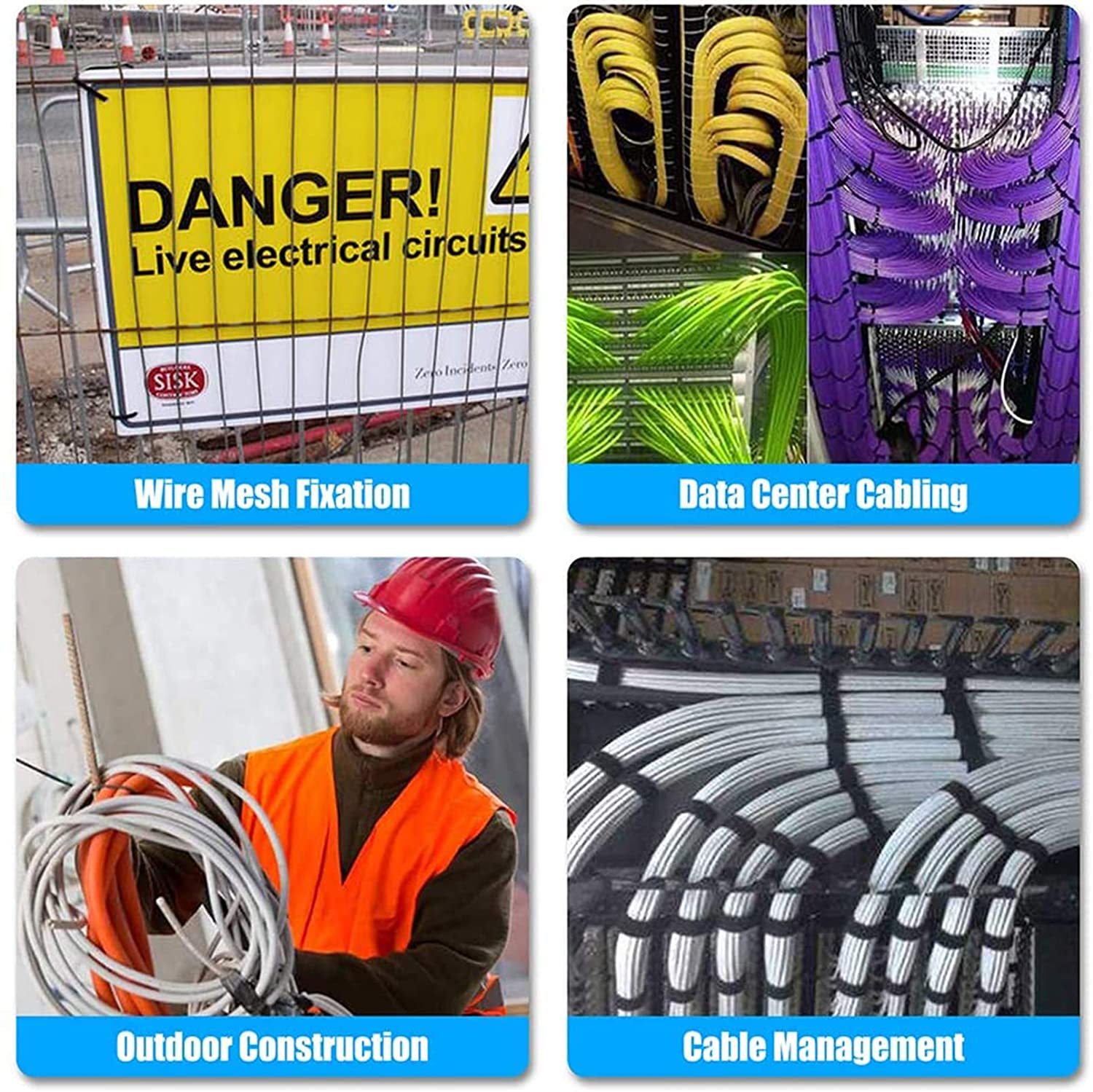

6. Tie products have the characteristics of fast binding, good insulation, self-locking fastening, and convenience of use. They can be applied to electronic factories, binding the internal wiring of televisions, computers, etc., fixing the internal lines of lighting, motors, electronic toys, etc., fixing the oil lines of mechanical equipment, fixing the cable lines on ships, fixing the entire bicycle packaging or binding other objects, and can also be used in agriculture, horticulture, handicrafts, etc. for binding items.

7. Tie wraps are widely used in Christmas gift factories, electronic factories, wire and cable processing plants, toy factories, festive holidays, stationery and general merchandise stores, fresh food supermarkets, household items, electrical workers, connectors, and other items for tying.

| Shop Details: |

|

|---|